The impact echo method was developed in the 1980's for the non destructive testing of concrete structures by the National Institute of Standards Technology (USA) and Cornell University (USA). It is expected that these two profiles, eventually combined with time frequency analysis of the signal, are an efficient way to detect voids in tendon ducts. Finally, a procedure that includes a thickness frequency profiles followed by void depth frequency profile is proposed.

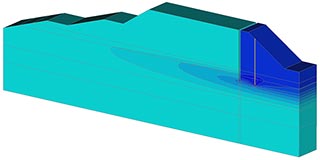

It is shown that for small void, the void depth frequency can be mislead with multiples of the thickness frequency especially when no frequency profile are carried out. The results are presented as frequency profiles in order to reproduce numerically a robust experimental procedure. To gain insight in the limits of detection of this void depth frequency, and in order to understand the physics of the multiple reflections that exist between the surface and the circular void, some finite element modelling has been undertaken. The second phenomenon does not appear to be easily observed in the field. It has been stated that a void causes a decrease of the thickness frequency of the slab as well as the appearance of a frequency peak indicative of the depth of the void that is different by a factor around two of that of a filled duct. LCPC - BP 4129 - F44340 Bouguenais Cedex - impact echo method can be used to detect void in tendon duct in certain condition of void depth and void size. Start > Contributions > Posters > Tendon Ducts: Print International Symposium (NDT-CE 2003)Non-Destructive Testing in Civil Engineering 2003 Comments on void depth detection in tendon duct with the impact echo method based on finite element computations

0 kommentar(er)

0 kommentar(er)